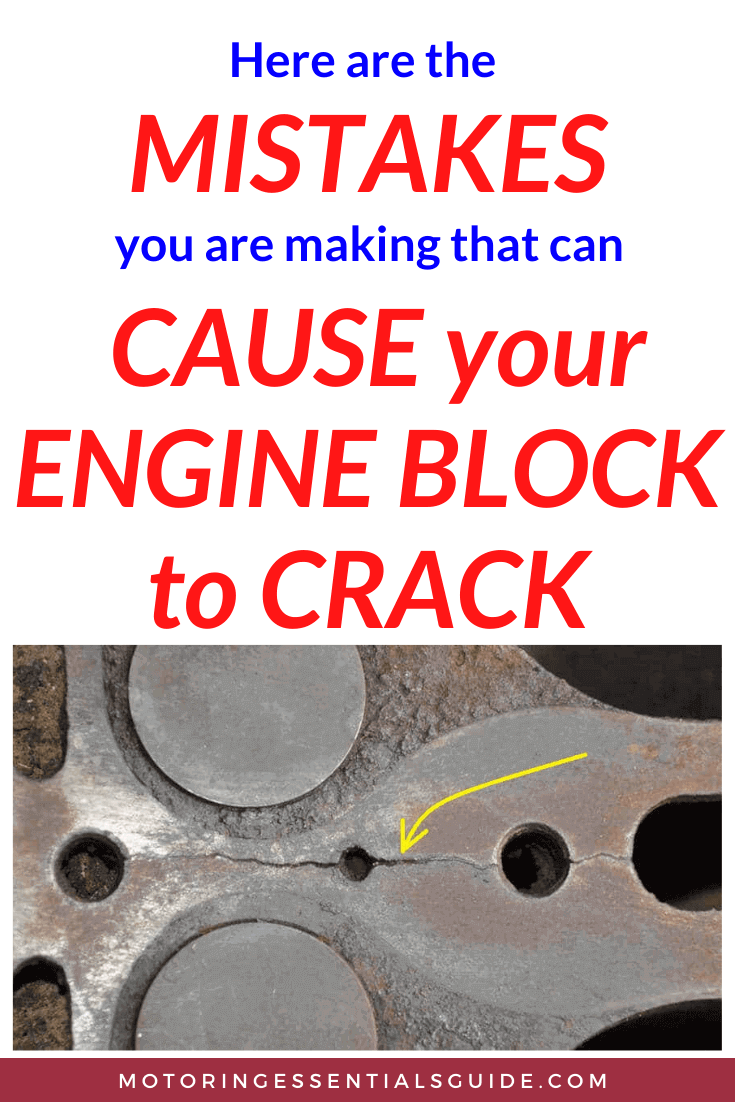

A cracked engine block is one of the automobile problems that greatly affect the performance of a car and can be way too problematic to repair. Replacing the entire engine is very pricy and it is not guaranteed that the car will function as well as it was when new. Apart from that, some engines are not replaceable at all.

You will have to seal the crack, through methods such as welding or using the best epoxy for cracked engine block. Below are some causes of a cracked engine block that you should be cautious about to avoid this problem at all costs.

Overheating

An extremely high temperature is one of the most likely causes of a cracked engine block and can be avoided. Overworking the engine by introducing superchargers and turbochargers that are not compatible is a major cause of overheating because the engine is overpowered. This leads to an expansion in the block which results in a block fracturing simply because the coolant can’t handle the excess heat.

Low coolant

Running the car with the low coolant light on is another possible cause of a fissured engine block. The coolant system is unable to regulate the excess heat produced by the engine if it’s at a level lower than recommended. Lack of proper maintenance of the coolant and radiator over time can also result in a cracked engine block if they are not repaired on time.

Water pump failure

Even with a perfect coolant level, a non-functional water pump can still cause the car engine block to crack. Failure of the water pump affects the flow of water through the engine cooling system hence the coolant is not efficient at its task. This leads the engine to overheat which in turn results in a cracked block because the coolant is unable to regulate temperature.

Bad bearing in connecting rod

In instances when the bearing in the connecting rod is faulty, the rod can go through the engine block hence cracking it. It is always advisable to take your car for maintenance services to ensure that the bearing among other parts is properly adjusted to avoid such occurrences.

Broken valve springs

When the valve springs are broken, they can easily drop a valve into the piston. This will then cause the piston and the connecting rod to rift the engine block when you start the car. Check on your valve springs frequently to ensure that they are in good shape.

Broken cam drive chain

Another cause of a cracked engine block is a broken cam drive. It causes valves to open at the wrong time hence the piston and connecting rod come into contact with the block. This results in a crack gradually over time. The problem can also be prevented by checking the chain regularly to make sure that it is functioning properly.

Broken block casting

Although in rare cases, an uncalled-for shift in the mold of the block casting can occur. This results in thinning of some parts of the metal unlike the optimum thickness of the other parts which leads to a fractured block on the engine. A broken cast defect requires you to get a replacement of the mold from the manufacturer to prevent further damage from happening.